The packaging industry is in constant flux. Driven by evolving consumer demands, stricter regulations, and the ever-increasing need for efficiency, packaging equipment is becoming more sophisticated and demanding. At the heart of most packaging machinery lies the gear motor, a critical component responsible for providing the torque and speed needed for various operations, from conveying and filling to sealing and labeling. Selecting the right gear motor isn't simply a mechanical decision; it’s an engineering one with significant implications for performance, reliability, and overall cost. This article shares practical experience and considerations gained from the packaging equipment field, focusing on gear motor selection, particularly highlighting the solutions offered by MES-Drive.

The packaging landscape is undergoing a rapid transformation. E-commerce boom, sustainable packaging initiatives, and the rise of personalized packaging are all putting immense pressure on equipment. For example, the surge in online orders necessitates faster and more reliable packaging lines, capable of handling increased throughput. Simultaneously, consumers are demanding eco-friendly materials and designs, requiring specialized equipment and adjusted operational parameters. Automation is no longer a luxury; it’s a necessity to maintain competitiveness. This means gear motors must be compatible with advanced control systems, capable of precise movements, and robust enough to operate continuously under varying loads and conditions. The current economic environment, with rising energy costs and supply chain uncertainties, further emphasizes the need for energy-efficient and reliable solutions.

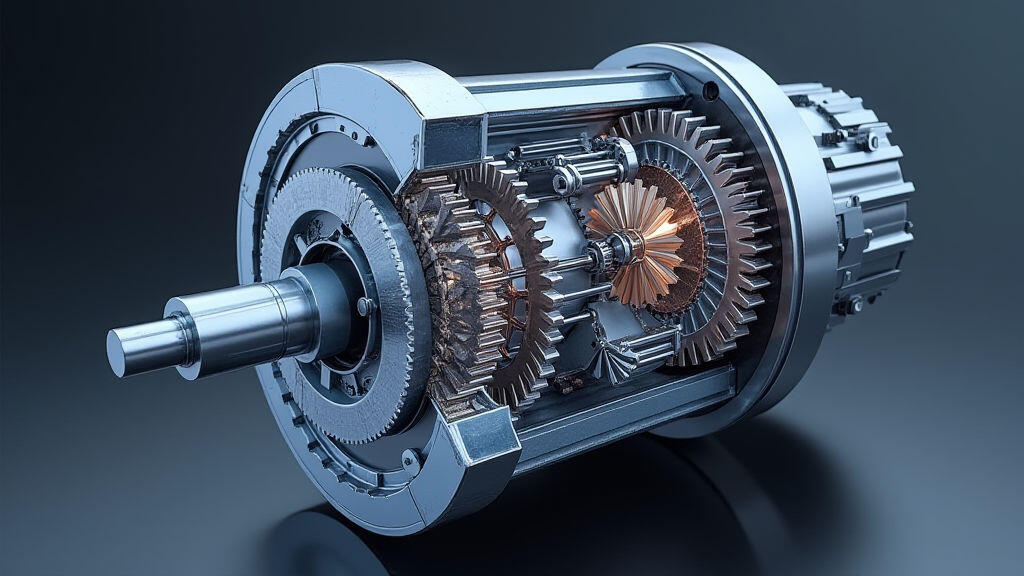

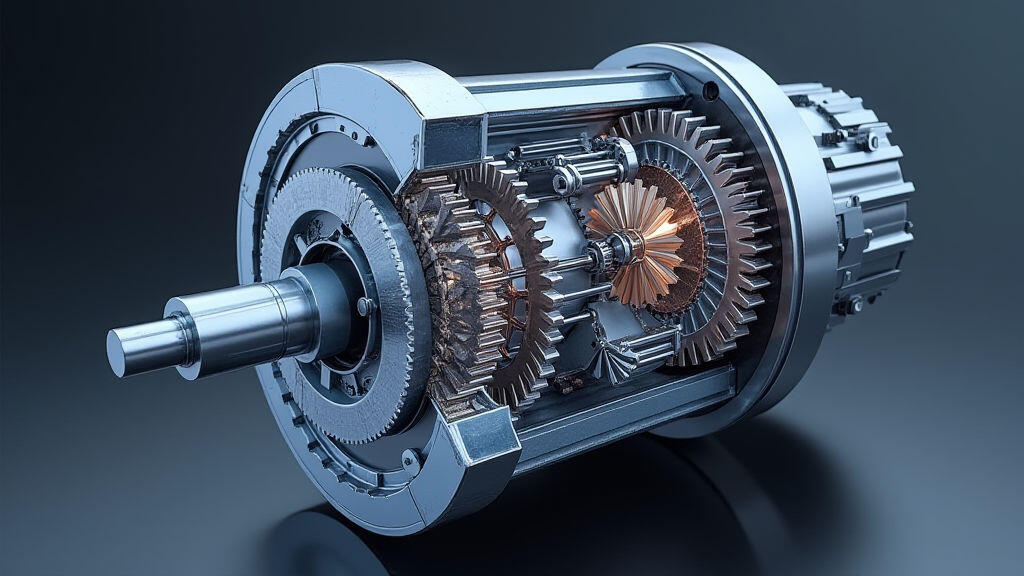

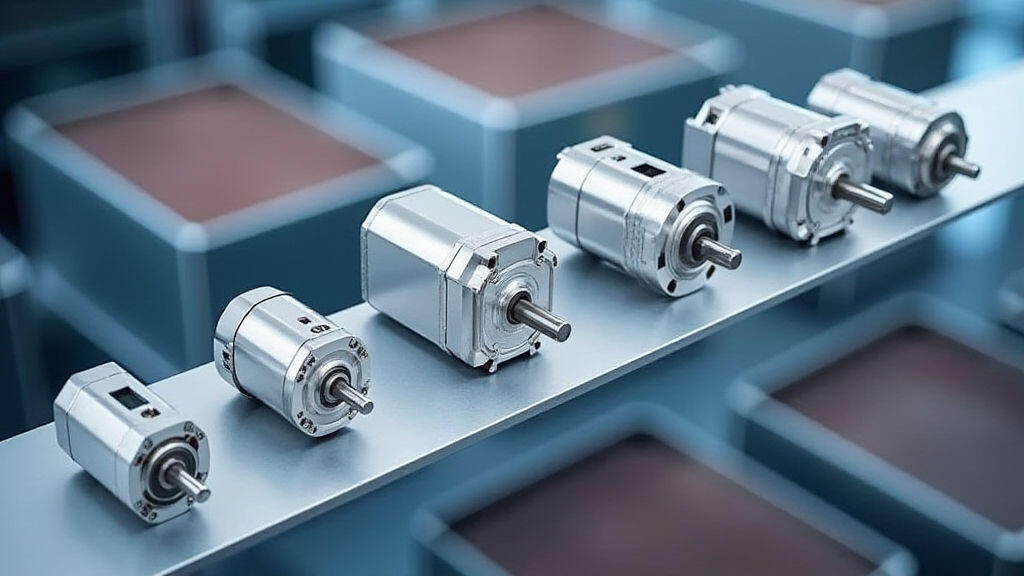

Several types of gear motors are commonly used in packaging equipment, each with its own advantages and disadvantages. The choice depends heavily on the specific application’s requirements.

Selecting a gear motor involves more than just matching torque requirements. Here’s a breakdown of critical factors to consider:

MES-Drive has been a trusted partner to packaging equipment manufacturers for [Number] years, providing a comprehensive range of high-quality gear motors tailored to the demands of the industry. We understand the specific challenges faced by packaging lines and offer solutions that prioritize reliability, efficiency, and performance.

Our gear motors feature:

One key area of focus for MES-Drive is integrating gear motors with smart control systems. Our motors are designed to seamlessly interface with Programmable Logic Controllers (PLCs) and servo drives, providing precise control and real-time performance monitoring. This enables predictive maintenance, minimizing downtime and maximizing productivity. For instance, our optimized worm gear motors, coupled with sophisticated encoder feedback, are used extensively in high-speed labeling applications, guaranteeing consistent and accurate label placement. We consistently see increased customer satisfaction when we provide a complete solution, including motor selection, integration, and ongoing support.

The rise of the Industrial Internet of Things (IIoT) is transforming the packaging industry. IoT sensors integrated with gear motors enable real-time monitoring of performance parameters like temperature, vibration, and current draw. This data can be analyzed to identify potential issues before they lead to downtime, facilitating predictive maintenance. MES-Drive is actively developing gear motors with integrated IoT capabilities, providing valuable data insights for optimized operation. This proactive approach not only reduces maintenance costs but also improves overall production efficiency. The growing importance of cybersecurity is also being addressed, with MES-Drive implementing robust security measures to protect data transmitted from our connected gear motors.

Selecting the right gear motor is a critical investment for packaging equipment manufacturers. By considering factors beyond just torque and speed - efficiency, duty cycle, environmental conditions, and control system compatibility - businesses can optimize performance, reduce costs, and ensure the long-term reliability of their equipment. MES-Drive is dedicated to providing cutting-edge gear motor solutions that meet the evolving needs of the packaging industry. With the increasing focus on automation, sustainability, and data-driven operations, gear motors are becoming increasingly sophisticated and integral to the entire packaging process. Embracing innovative solutions like those offered by MES-Drive, coupled with the insights gained from IoT and predictive maintenance, will be key to navigating the complexities of the future packaging landscape. The increasing demands in the e-commerce sector and the growing focus on sustainable packaging are driving the need for even more efficient and reliable gear motor solutions, positioning MES-Drive at the forefront of this vital technology.

Leave A Reply

Your email address will not be published. Required fiels are marked